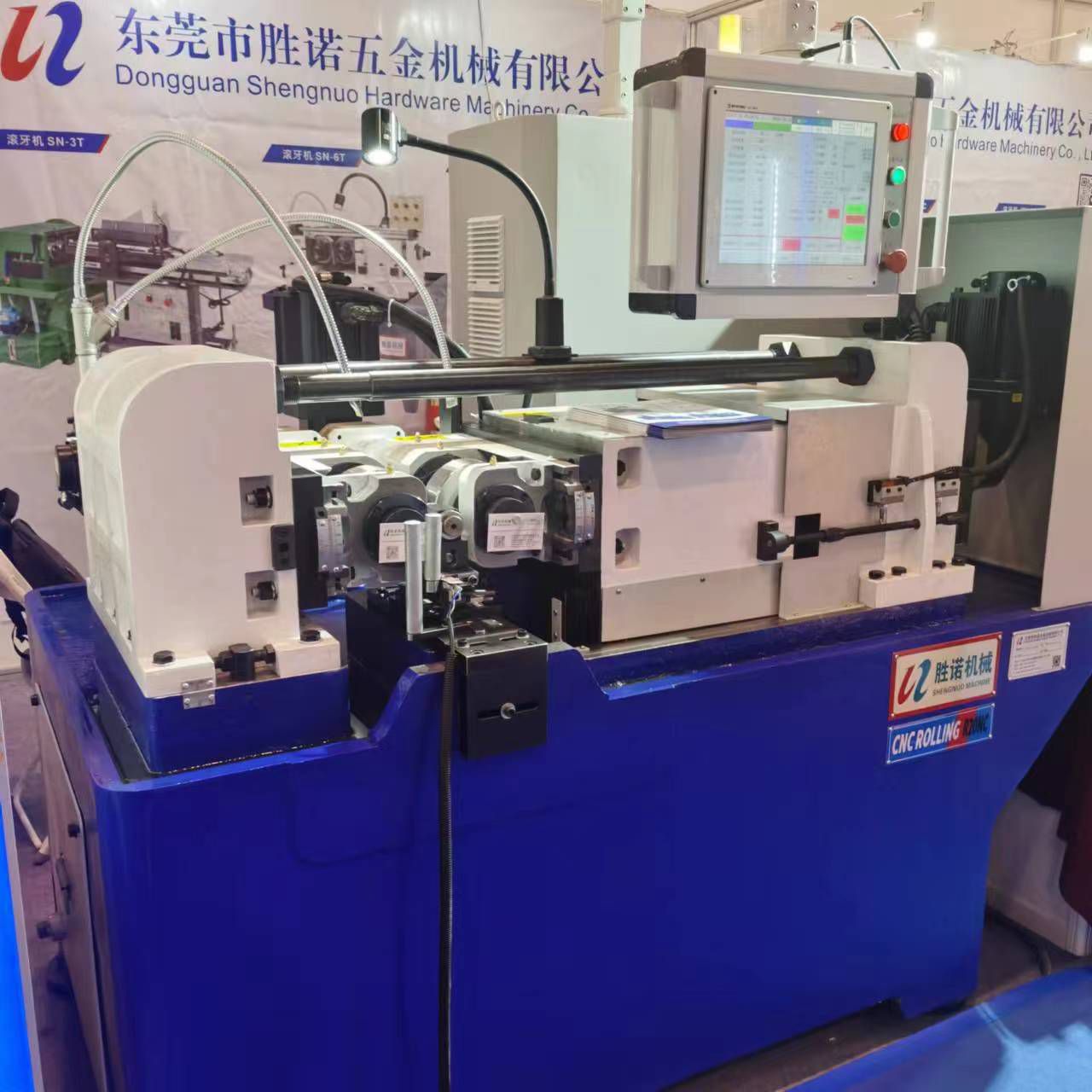

SUNNO High Precision CNC Wire Rolling Machine

|

Brand Name: |

SUNNO |

|

Model No.: |

R20NC |

|

Customized support: |

OEM |

Automatic CNC wire rolling machine in its rolling range of ordinary thread, twill, straight grain, bevel tooth, trapezoid thread, modulus thread rolling, straightening, rolling, reducing and a variety of forming rolling, the machine has a safe and reliable electric hydraulic execution and control mechanism.

The rolling cycle can be selected between manual and automatic (users can bring their own rollers according to their needs).

Details

The main features of this model:

A. Model code is servo motor drive, maximum output 20Tons.

B. The following workpieces can be made according to the type of the roller:

1. [Fixed rolling] : Generally 55 degrees and 60 degrees pointed standard thread, outside the workpiece

Diameter ≥φ40MM, pitch 5.0MM, the longest thread rolling on the workpiece is infinite.

2.[Rolling type rolling] Standard thread pitch =5.0MM, outside diameter and length are not limited.

C. Structural features: The two-roller shaft is driven by servo motor, and the feed shaft is driven by servo motor

Ball screw feed.

D. This tooth rolling machine can also process a variety of tooth shape products, such as: worm teeth, trapezoid teeth and so on

The drawing depends on it.

Main equipment configuration:

1. The machine adopts gas servo driving force, high repeatability and high torque.

2. Electric control system. Programmable controllers (PLCS) use Taiwanese and Japanese products.

Man-machine panel digital display speed. Reliable quality and easy maintenance.

3. Each Yan safety is fully protected, and protective devices and warning signs are set at dangerous places (or

Symbol), convenient for machine running state observation, operation adjustment and maintenance.

4. Random tools, according to the factory standard equipped with complete technical information.

PARAMETER

1 Rolling the maximum outer diameter of the workpiece 40mm

Maximum workpiece pitch 5mm (rolling, extrusion pitch: 15mm)

Custom rolling range 42mm

The scope of the rolling system is unlimited

2 Roller speed The roller speed ranges from 0 to 80rpm

3 Roller dimensions The maximum outer diameter of the roller is 180mm

Inner hole of the roller 54mm

Maximum length of roller 140mm

4 Transmission horsepower roller rolling pressure 20T

Spindle servo motor power 2×5.5Kw

Feed servo motor power 5.5Kw

5 Spindle center height 160mm

6 New generation of servo control system (secondary development)

7 Field area 1870×1060(mm2)

8 Total machine height 1930mm

9 Total weight of the machine 2900Kg

10 Thread type Processing thread type Standard teeth, trapezoid teeth, worm teeth, straight grain, mesh

11 Feed speed Slide forward speed servo feed, may be accurate to 0.001mm

12 Spindle mechanical Angle Spindle deflection Angle can be adjusted respectively ±10°

13 Rolling time Rolling pressure time None Adjustable ≤0.1s May be adjusted according to rolling work

Rolling time setting resolution

14 Machine tools delivered

Accuracy check spindle runout accuracy ≤0.01mm

Spindle repeated positioning accuracy ≤0.003mm

Spindle outer diameter -0.02mm

15 Machine tool commissioning operation panel 15 "touch full screen

Roller to floss 0.1-360 degree servo adjustment

Slow distance system setting

Back off distance system setting

Rolling processing time 0.1-100s system setting

Other tuning parameters system Settings

16 Machine commissioning roller to floss 15 "touch full screen

Rolling mode Rolling mode

Fixed point rolling mode Fixed point rolling

Fixed rolling mode system Settings, adjust according to customer needs

Continuous rolling mode

Split rolling mode

Rolling mode

GET A QUOTE

.jpg)